Project Description

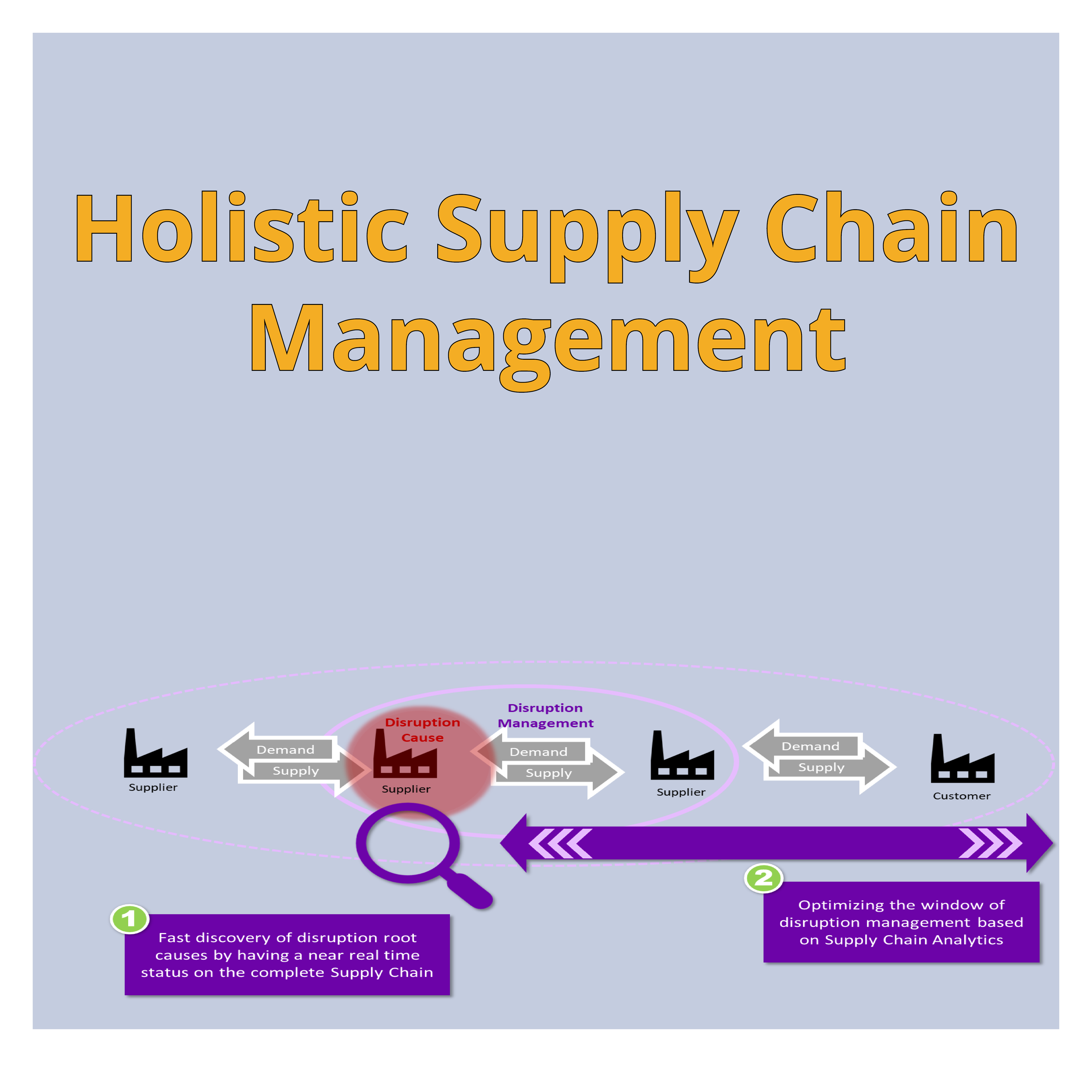

Holistic Supply Chain

Holistic Supply Chain Tool enables complex Supply Chains with several product transformations to talk in a Common Language and gain Competitive Advantages by having a near real-time complete Supply Chain status overview related to individual Demand behaviors and Stock levels.

There will be minimum implementation efforts and fast start-up times as our system is not invasive and does not require any changes in current ERP-systems and ordering-forecasting procedures.

The Holistic Supply Chain Software can be used during:

- Regular operating modes,

- Model changes, and

- Catastrophes causing severe Supply Chain disruptions

What it is

the Holistic Supply Chain Tool will enable complex supply chains with several product transformations to talk in a common language and have a near real-time overview on the supply chain stock and demand behaviors amongst supply chain members

What makes it different

- The Holistic Supply Chain tool does not focus on warehousing, transport and customs control, instead it compares demand developments with stocks across the Supply Chain

- Our tool goes beyond a two-node communication whereas practically all other Supply Chain tools focus on a set of two nodes in the chain on a customer-supplier basis

- By creating a common language communication will be much more efficient across Supply Chains

- The Holistic Supply Chain software is using a non-invasive (no access through firewalls required) data extraction method and thereby has a very short implementation time

- There will be minimum implementation efforts and fast start-up times as our system does not require any changes in current ERP-systems and ordering-forecasting procedures.

- See the Presentation and Video explanations on our Home Page

What it brings for your company

by having demand development data and stock levels across the Supply Chain you will be able to:

- Recognize Overstocks and (potential) stock shortages,

- Manage Model Phase-Outs much better,

- Recognize Bullwhip effects anywhere in the supply chain,

- Simulate What-if scenarios in case of short term demand changes, and

- Calculate the number of Survival Days in case of catastrophes